Ductile Iron Pipes Overview

Ductile Iron is an improved variety of Cast Iron invented in 1949.

It is also known as Spheroidal Graphite Iron or Nodular Cast Iron.

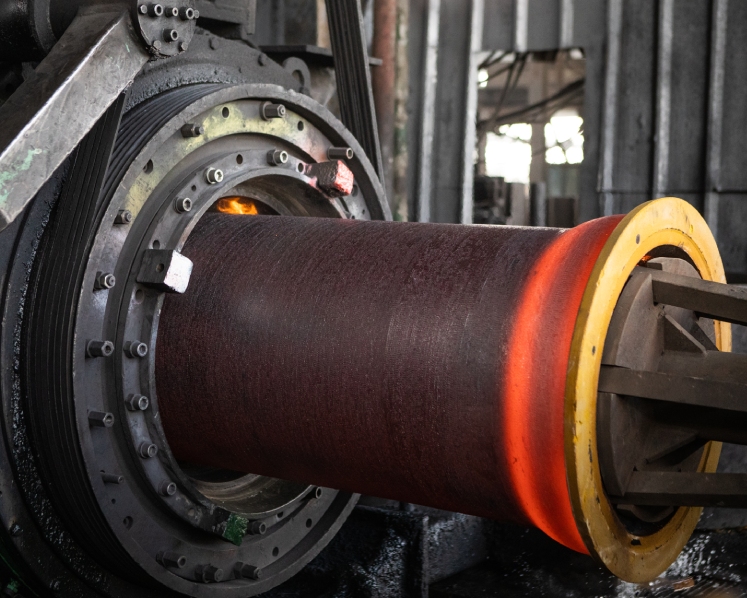

Centrifugally cast Ductile Iron pipes are one of the most preferred materials for water supply and sewerage applications across the world due to its host of advantages.

Pipes made from Ductile Cast Iron provide substantial benefits in terms of pressure bearing ability, impact resistance and capacity to sustain external static/ dynamic loading.

Protection System

- Internal lining

Cement Mortar Lining

For Drinking water pipelines Acc. to ISO 4179

GCF used sulphate resistant cement (SRC)

For Sewage and industrial Pipelines Acc. to EN 598

GCF used High alumina Cement (HAC)

- External Coating

Acc. to ISO 8179 & EN 545

- Metallic zinc 130 g/m2 with finishing layer bitumen 70 μ.

- Zinc Aluminum alloy400 g/m2 with finishing layer bitumen70μ.

Ductile Iron Pipes

Ductile Iron Pipes Used Applications

Mechanical Properties

According to ISO 2531 & EN 545

-

Tensile Strength

Min. 420 MPa -

Elongation (min) at break

10% -

Hardness

Max. 230 BHN

Product Details

Ductile Iron pipes made by GCF conform to the following International standards ISO 2531 & EN 545

Let’s Talk