Archives: Products

Ductile Iron Fittings & Accessories

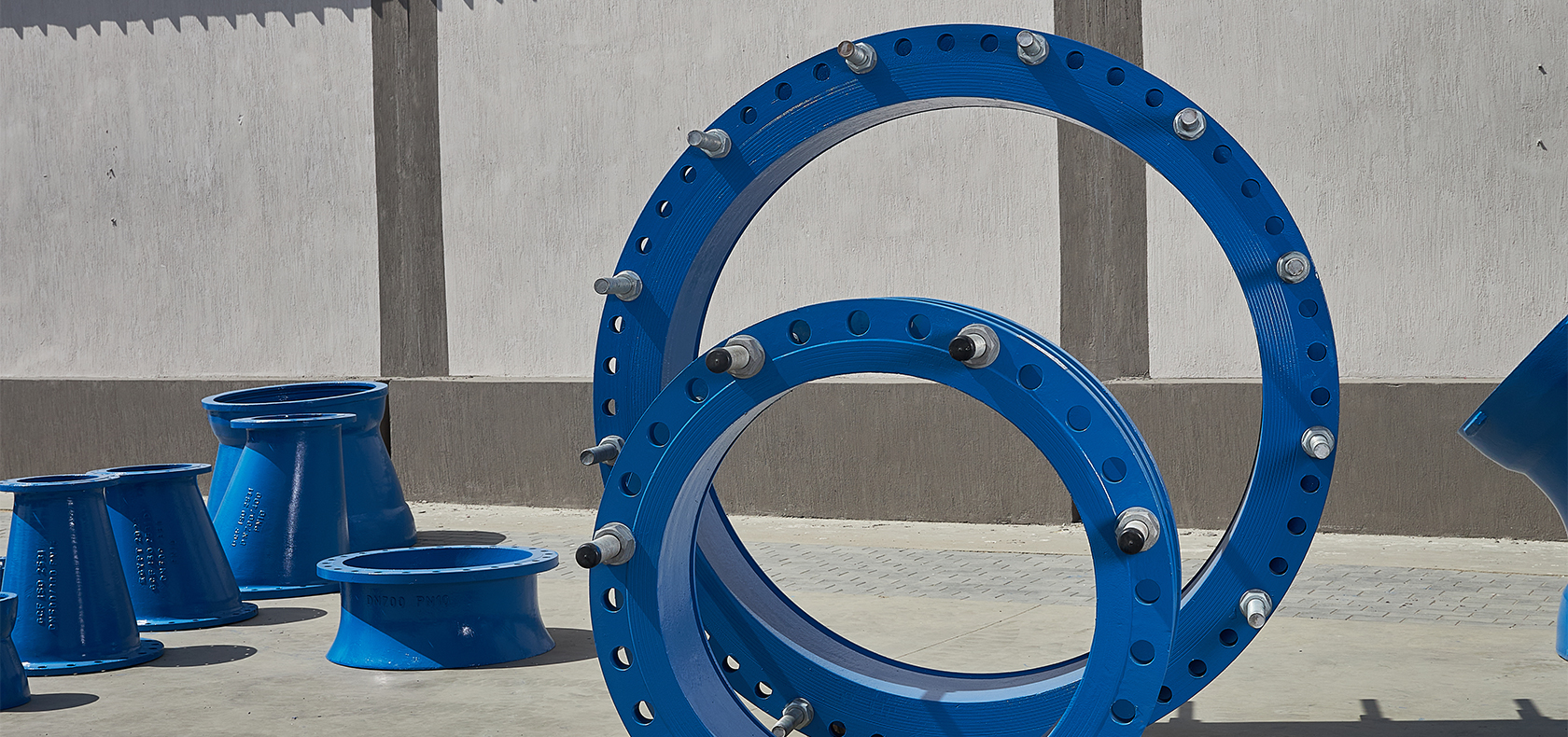

Ductile Iron Fittings: Enhancing Infrastructure Solutions at Greater Cairo Foundries

Overview of Ductile Iron Fittings and Flanged Pipes at Greater Cairo Foundries

At Greater Cairo Foundries (GCF), we pride ourselves on offering a comprehensive range of standard ductile iron fittings and flanged pipes that comply with the highest international standards, specifically ISO 2531 and EN 545. Our product line is designed to meet a diverse array of needs, ensuring that our clients have access to high-quality components for various applications.

Product Range and Specifications

Our ductile iron fittings and flanged pipes are available in a wide range of sizes, from 80 mm to 2600 mm. This extensive size range allows us to cater to numerous project requirements, from small-scale installations to large infrastructure projects. We also offer products with varying nominal pressures, including PN 10, PN 16, and PN 25, providing the flexibility needed to handle different pressure requirements effectively.

In addition to our standard fittings and flanged pipes, GCF is equipped to manufacture non-standard fittings with customized dimensions. We understand that each project can present unique challenges, and standard components may not always fit perfectly. Our ability to produce non-standard items quickly ensures that our clients can overcome these obstacles without significant delays.

Understanding Installation Challenges

At GCF, we are acutely aware of the difficulties that can arise during the installation of ductile iron fittings and pipes. On-site conditions can vary greatly, and unexpected issues can lead to delays and additional costs. To address these challenges, we have honed our capabilities to deliver custom solutions rapidly. Our team works closely with clients to understand their specific needs and provide tailored fittings that meet their precise requirements.

Product Classification

Our ductile iron fittings and flanged pipes are classified by joint type to help our clients easily find the products that best suit their projects:

- Socket Type Fittings: These fittings are designed for easy and secure connections, providing reliable performance in a variety of applications.

- Flanged Type Fittings: Flanged fittings offer robust connections ideal for high-pressure environments and ensure a secure and leak-proof seal.

- Flanges and Fabricated Pipes: Our range includes various flanges and fabricated pipes, which are essential components for many piping systems.

Commitment to Quality and Service

At GCF, quality and customer satisfaction are at the forefront of everything we do. Our adherence to ISO 2531 and EN 545 standards guarantees that our products meet rigorous quality benchmarks. We are committed to delivering exceptional service, whether through our standard product offerings or custom solutions. Our rapid delivery of non-standard items underscores our dedication to meeting our clients’ needs promptly and efficiently.

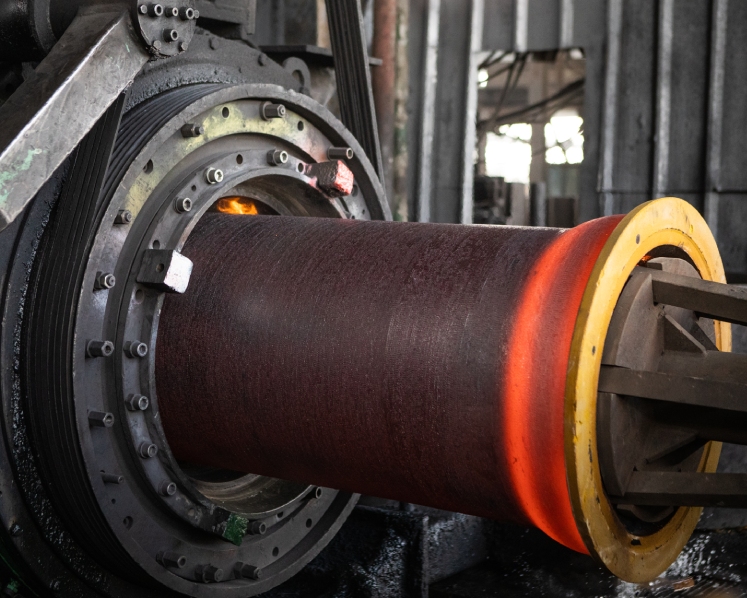

Jobbing

Jobbing at Greater Cairo Foundries Overview Greater Cairo Foundries (GCF) has established itself as a leading jobbing foundry, evolving from its humble beginnings to become the largest foundry in the Middle East and North Africa. Our commitment to quality, precision, and customer satisfaction sets us apart in the industry, allowing us to deliver a wide range of castings that meet the specific needs of our clients. Comprehensive Range of Castings At GCF, we offer an extensive array of castings in various sizes and materials, including ductile iron, steel, alloy steel, and alloy cast iron. Our ability to handle diverse materials and complex geometries makes us a versatile partner for numerous industries. From small components to large-scale castings, we ensure each product meets the highest standards of quality and durability. The Jobbing Process Our jobbing process is meticulously designed to ensure precision and efficiency at every stage:

-

Pattern Making: Skilled artisans craft intricate patterns that serve as templates for the molds.

-

Molding: These patterns are used to create molds using techniques such as green sand or investment casting.

-

Melting and Pouring: The chosen metal is melted and carefully poured into the molds.

-

Cooling and Finishing: The castings undergo controlled cooling, followed by cleaning and finishing to meet precise specifications.

This detailed process allows us to produce high-quality castings with minimal lead times and competitive pricing. Customization and Flexibility One of the key advantages of our jobbing services is the ability to provide tailored solutions. We understand the unique challenges our customers face during installation and offer customized fittings to meet their specific requirements. This flexibility extends to low to medium volume productions, ensuring we can accommodate a wide range of project sizes and scopes. Industry Applications GCF’s jobbing services are utilized across various industries, including automotive, construction, aerospace and defense, industrial machinery, energy and power generation, mining and minerals processing, and rail and transportation. Our products are designed to meet the rigorous demands of these sectors, providing reliable performance and durability. Commitment to Excellence At Greater Cairo Foundries, we pride ourselves on delivering high-quality products and exceptional customer service. Our commitment to working hand-in-hand with clients to understand their needs and provide customized solutions ensures that we consistently exceed expectations. With a focus on innovation and precision, GCF is your trusted partner for all your casting needs.

Metal Seated Gate Valves

Metal Seated Gate Valves: Ensuring Reliability and Performance

Greater Cairo Foundries (GCF) takes pride in its extensive range of metal seated gate valves, meticulously crafted from ductile iron to meet the highest standards of quality and durability. These valves serve as vital components in various industrial applications, providing reliable performance and exceptional longevity.

Quality Assurance in Gate Valves Production

At GCF, every step of the production process is governed by strict quality assurance protocols. From the selection of raw materials to the final inspection of finished products, we adhere to rigorous standards to ensure that our metal seated gate valves meet or exceed industry requirements. Our commitment to quality is evident in the durability and reliability of our valves, making them the preferred choice for critical applications.

Global Reach: Exporting Gate Valves to Over 14 Countries

With a reputation for excellence, GCF has successfully exported its metal seated gate valves to more than 14 countries across the globe. Our valves have earned the trust of customers worldwide, thanks to their superior performance, robust construction, and adherence to international quality standards. Whether used in water distribution systems, sewage treatment plants, or industrial facilities, our valves consistently deliver exceptional results.

Versatility and Applications of Gate Valves

Metal seated gate valves manufactured by GCF are renowned for their versatility and suitability for a wide range of applications. From controlling the flow of water in municipal pipelines to regulating the passage of fluids in industrial processes, our valves excel in diverse environments. Their robust construction and metal-seated design make them ideal for handling abrasive or corrosive fluids, ensuring reliable operation even in the harshest conditions.

Commitment to Continuous Improvement

At GCF, we are committed to continuous improvement in our gate valve offerings. Through ongoing research and development initiatives, we strive to enhance the performance, efficiency, and lifespan of our valves. By incorporating the latest advancements in materials science and engineering techniques, we ensure that our products remain at the forefront of innovation, meeting the evolving needs of our customers worldwide.

Partnering for Success: Metal seated ductile iron gate valves from Greater Cairo Foundries

Metal Seated Gate Valves: Engineered Excellence from Greater Cairo Foundries Introduction Greater Cairo Foundries (GCF) stands at the forefront of manufacturing excellence, producing high-quality metal seated gate valves crafted from ductile iron. With a steadfast commitment to quality assurance and precision engineering, our valves have earned international acclaim, being exported to over 14 countries worldwide. Let's delve into the unparalleled features and benefits of our metal seated gate valves. Engineering Superiority At Greater Cairo Foundries, we prioritize engineering excellence in every aspect of our production process. Our metal seated gate valves are meticulously designed to withstand the most demanding environments, providing reliable performance and long-term durability. Crafted from premium-grade ductile iron, these valves exhibit exceptional strength and corrosion resistance, ensuring extended service life even in harsh operating conditions. Stringent Quality Assurance Quality assurance is the cornerstone of our manufacturing ethos at GCF. We adhere to stringent quality control measures at every stage of production, from raw material procurement to final inspection. Our state-of-the-art facilities and rigorous testing protocols guarantee that each metal seated gate valve meets or exceeds industry standards for performance, reliability, and safety. Global Reach and Reputation With a proven track record of excellence, GCF has successfully penetrated international markets, exporting our metal seated gate valves to more than 14 countries across the globe. Our valves have earned widespread recognition for their superior quality, earning the trust and confidence of customers worldwide. Whether used in water distribution systems, sewage treatment plants, or industrial applications, GCF valves consistently deliver exceptional performance and reliability. Versatile Applications GCF's metal seated gate valves find application in a diverse range of industries and environments. From municipal water supply networks to wastewater treatment facilities, our valves play a crucial role in controlling the flow of fluids with precision and efficiency. Designed to handle varying pressures and temperatures, our valves offer unmatched versatility, making them ideal for a wide spectrum of applications. Customer-Centric Solutions At Greater cairo foundries, we prioritize customer satisfaction above all else. Our dedicated team works closely with clients to understand their unique requirements and provide tailored solutions that meet their specific needs. Whether it's customizing valve dimensions or incorporating special features, we go above and beyond to ensure complete customer satisfaction. Our commitment to excellence extends beyond product quality to encompass superior service and support, fostering long-term partnerships with our valued clients. Greater Cairo Foundries (GCF) prides itself on its ability to innovate and adapt to evolving industry demands. Our continuous investment in research and development ensures that our metal seated gate valves remain at the forefront of technological advancements, offering cutting-edge solutions for the most challenging applications worldwide. With a legacy of excellence spanning decades, GCF is your trusted partner for superior valve solutions.

Sewage Air Valves

Sewage Air Valves: Enhancing Pipeline Efficiency and Safety

Discover Our Range of Sewage Air Valves

Compliance Assured: Sewage Air Valves Built to AWWA C512 Standard

Efficient Air Release: Hydro-Mechanical Design for Seamless Operation at Sewage air valve models

Critical Applications: Sewage Air Valves for Transmission Lines and Treatment Plants

Boost Performance: Applications in Sewage Transmission and Irrigation Systems by using greater cairo foundries sewage air valves

Optimizing Pipeline Performance with Sewage Air Valves from Greater Cairo Foundries

Sewage air valves play a crucial role in the efficient operation of sewage transmission lines, wastewater treatment plants, and irrigation systems. At Greater Cairo Foundries (GCF), we specialize in the production of high-quality sewage air valves designed to enhance pipeline efficiency and safety.

Hydro-Mechanical Design for Reliable Operation

Our sewage air valve series 6500 is designed as hydro-mechanical devices capable of automatically releasing or admitting air during pipeline filling, draining, or operation. This innovative design ensures the continual removal of air from the pipeline, safeguarding the system against potential issues such as air locks and ensuring smooth operation.

Compliance with Industry Standards

At GCF, we adhere to the highest industry standards to ensure the quality and reliability of our products. Our sewage air valves are manufactured in accordance with the standard AWWA C512, guaranteeing compliance with stringent performance and safety requirements. This commitment to quality assurance ensures that our valves meet the needs of even the most demanding applications.

Critical Applications in Sewage Transmission and Treatment

Our sewage air valves find application in a variety of critical settings, including sewage main transmission lines, wastewater treatment plants, and irrigation systems. In these environments, the efficient removal of air from the pipeline is essential for maintaining system integrity and performance. Our valves are designed to operate reliably even in the presence of solids and debris in suspension, ensuring uninterrupted operation.

Enhancing Efficiency and Safety

By incorporating GCF sewage air valves into their infrastructure, organizations can enhance the efficiency and safety of their pipeline systems. Our valves provide seamless air release and admission, reducing the risk of air locks and ensuring consistent flow throughout the pipeline. This not only improves operational efficiency but also helps to minimize the risk of costly downtime and repairs.

Conclusion

Sewage air valves are essential components in sewage transmission and treatment systems, ensuring the efficient operation and safety of pipeline infrastructure. With our range of high-quality sewage air valves, Greater Cairo Foundries is committed to providing reliable solutions that meet the needs of our customers. By choosing GCF sewage air valves, organizations can optimize the performance of their pipeline systems and ensure long-term reliability and efficiency.

Stay Updated! Follow Our Latest News and Insights on Facebook and LinkedIn

Water Air Valves

Water Air Valves: Optimizing Pipeline Efficiency and Safety

Explore Our Range of Water Air Valves

Reliable Functionality: Water Air Valves for Seamless Pipeline Operations

Features of GCF Series 6200 & 6300

Critical Applications: Water Air Valves for Main Transmission Lines and Pumping Stations

Enhancing Performance: Applications in Water Transmission and Irrigation Systems

Improving Pipeline Efficiency with Water Air Valves from Greater Cairo Foundries

Water air valves are essential components in water transmission and irrigation systems, ensuring the efficient operation and safety of pipeline infrastructure. At Greater Cairo Foundries (GCF), we specialize in the production of high-quality water air valves designed to optimize pipeline efficiency and safety.

Seamless Pipeline Operations

Our water air valves series 6200 and 6300 are meticulously engineered to provide reliable functionality and seamless pipeline operations. The series 6200 features a double-chamber design without internal isolation, while the series 6300 includes internal isolation for added versatility. Both designs allow for automatic air release and admission during pipeline filling and emptying, ensuring undisturbed pipeline operation.

Versatile Applications

The GCF water air valves find application in a variety of critical settings, including water main transmission lines, water pumping stations, and irrigation systems where solids are not present. These valves play a crucial role in maintaining pipeline integrity and preventing issues such as airlocks, ensuring consistent water flow and system efficiency.

Quality Assurance

At GCF, quality assurance is paramount in every aspect of our manufacturing process. Our water air valves are constructed from high-grade ductile iron, ensuring durability and reliability in demanding environments. Each valve undergoes rigorous testing and inspection to ensure compliance with industry standards and performance requirements.

Enhancing Safety and Efficiency

By incorporating GCF water air valves into their infrastructure, organizations can enhance the safety and efficiency of their water transmission and irrigation systems. The automatic air release and admission feature of our valves reduce the need for operator intervention, minimizing the risk of human error and ensuring uninterrupted pipeline operations.

Conclusion

Water air valves are essential components in water transmission and irrigation systems, ensuring the efficient operation and safety of pipeline infrastructure. With our range of high-quality water air valves, Greater Cairo Foundries is committed to providing reliable solutions that meet the needs of our customers. By choosing GCF water air valves, organizations can optimize the performance of their pipeline systems and ensure long-term reliability and efficiency.

Health and safety:

At Greater Cairo Foundries, stringent health and safety procedures are meticulously followed during the manufacturing of water air valves to ensure the well-being of our employees and the integrity of our products. Our facility is equipped with advanced safety measures and protocols to mitigate risks and prevent accidents. Regular safety training sessions are conducted for all employees to promote awareness and adherence to safety guidelines. Additionally, comprehensive inspections and audits are carried out to identify and address any potential hazards promptly. By prioritizing health and safety, we create a secure working environment that fosters employee well-being and product quality.

Quality assurance:

In tandem with our commitment to health and safety, Greater Cairo Foundries upholds strict quality assurance protocols throughout the manufacturing process of water air valves. Each stage of production undergoes rigorous inspection and testing to ensure adherence to industry standards and specifications. Our experienced team of engineers and technicians meticulously monitor every aspect of production, from material sourcing to final assembly, to guarantee the reliability and performance of our water air valves. By maintaining uncompromising standards of quality assurance, we instill confidence in our customers, knowing they can rely on our products for superior performance and durability.

Stay Updated! Follow Our Latest News and Insights on Facebook and LinkedIn

Dismantling Joints

Reliable Mechanical Joints for Flanged Pipelines

Versatile Applications of GCF Mechanical Joints

Types of Mechanical Joints Available

Restrained Dismantling Joints (Type B)

Flexible Dismantling Joints

Quality Assurance and Safety Procedures

Reliable Mechanical Joints for Flanged Pipelines

At Greater Cairo Foundries (GCF), we pride ourselves on manufacturing high-quality mechanical joints designed for joining two flanges to create gaps or spaces in flanged pipelines. Our mechanical joints facilitate the quick installation and removal of valves and pumps, making them ideal for applications where periodic maintenance or modifications are required. Available in sizes ranging from DN80 to DN2600, our mechanical joints can be tailored to virtually any flange drilling or pressure rating, with custom designs available upon request.

Versatile Applications of GCF Mechanical Joints

GCF mechanical joints are used in a variety of applications, including pumping stations, water treatment works, sewage treatment works, and washing and air chambers. These joints provide the necessary axial movement to facilitate the dismantling of equipment, ensuring a seamless maintenance process. Our comprehensive range of mechanical joints meets the demands of various industries, providing reliable and durable solutions for pipeline systems.

Types of Mechanical Joints Available

GCF offers two primary types of mechanical joints to meet the diverse needs of our customers:

- Restrained Dismantling Joints (Type B)

- Flexible Dismantling Joints

Restrained Dismantling Joints (Type B)

Our restrained dismantling joints are designed to provide axial restraint in pipeline systems. These joints are ideal for applications where a secure and stable connection is required, preventing any movement that could compromise the integrity of the pipeline. With a focus on durability and reliability, our restrained dismantling joints are manufactured to the highest standards, ensuring long-lasting performance in demanding environments.

Flexible Dismantling Joints

Flexible dismantling joints offer the advantage of allowing some degree of movement within the pipeline system. This flexibility is particularly useful in applications where minor adjustments are needed to accommodate changes in pipeline alignment or thermal expansion. Our flexible dismantling joints are engineered to provide a reliable connection while accommodating the necessary movement, ensuring the smooth operation of the pipeline.

Quality Assurance and Safety Procedures

At GCF, we prioritize quality and safety in every aspect of our manufacturing process. Our mechanical joints are produced in accordance with stringent quality assurance protocols to ensure they meet the highest standards. Each joint undergoes rigorous testing and inspection to verify its performance and durability. By maintaining strict quality control measures, we ensure that our mechanical joints provide reliable and efficient solutions for our customers.

Health and Safety Procedures Followed at Greater Cairo Foundries

Health and safety are paramount at Greater Cairo Foundries. We implement comprehensive safety procedures to protect our employees and ensure a safe working environment. Our manufacturing processes are designed to minimize risks and prevent accidents. Regular safety training and drills are conducted to keep our workforce well-informed and prepared. We also invest in state-of-the-art safety equipment and technologies to enhance workplace safety. By adhering to these stringent safety measures, we ensure that our production processes are safe and efficient.

Quality Assurance at Greater Cairo Foundries

Quality assurance is a cornerstone of our operations at GCF. We adhere to international standards and best practices to ensure the highest quality of our products. Our mechanical joints undergo multiple stages of quality checks, from raw material selection to final inspection. We utilize advanced testing methods to evaluate the performance, durability, and reliability of our joints. Our commitment to quality assurance ensures that our products meet and exceed customer expectations, providing dependable solutions for a variety of applications.

5. Health and Safety Procedures

At Greater Cairo Foundries, the health and safety of our employees are of utmost importance. We follow comprehensive health and safety procedures to ensure a safe working environment during the manufacturing of mechanical joints. Our facility is equipped with advanced safety equipment, and our workforce undergoes regular training to stay updated on the latest safety protocols. We conduct frequent safety audits and inspections to identify and mitigate potential hazards. By fostering a culture of safety, we not only protect our employees but also enhance the overall efficiency and quality of our manufacturing processes.

Quality Assurance Procedures

Quality assurance at Greater Cairo Foundries is a rigorous process that ensures every mechanical joint meets the highest standards of performance and durability. From the selection of raw materials to the final inspection, each stage of production is meticulously monitored and tested. Our mechanical joints are manufactured in accordance with international standards, including ISO and BS certifications. We employ advanced testing techniques to assess the structural integrity and functionality of our products. Our commitment to strict quality assurance protocols guarantees that our mechanical joints provide reliable and efficient solutions for our customers, enhancing the performance and longevity of their pipeline systems.

Stay Updated! Follow Our Latest News and Insights on Facebook and LinkedIn

Flanged Adaptor

Flanged Adaptors for Efficient Installations

Versatile Range of Flanged Adaptors

Applications of Flanged Adaptors

Key Features of Flanged Adaptors

Health and Safety Procedures

Quality Assurance at Greater Cairo Foundries

Overview of Mechanical Joints

Mechanical joints are crucial components in various piping systems, facilitating easy installation, maintenance, and modifications. Greater Cairo Foundries (GCF) excels in producing high-quality ductile iron mechanical joints, which are essential for ensuring the durability and efficiency of pipeline systems.

Types of Mechanical Joints

GCF offers two main types of mechanical joints:

Restrained Dismantling Joints (TYPE B): These joints are designed to prevent axial movement, providing a secure and stable connection between pipeline components. They are ideal for applications where maintaining alignment and preventing separation under pressure are critical.

Flexible Dismantling Joints: These joints allow for axial movement, making them suitable for installations where flexibility is required. They facilitate the easy removal and replacement of valves, pumps, and other equipment in the pipeline.

Applications of Mechanical Joints

GCF’s mechanical joints are widely used in various sectors, including:

Pumping stations

Water treatment works

Sewage treatment works

Washing and air chambers

These joints are designed to withstand the demanding conditions of these applications, ensuring long-lasting performance and reliability.

Key Features of Mechanical Joints

Wide Range: GCF offers mechanical joints in sizes ranging from DN80 to DN2600, catering to a broad spectrum of pipeline diameters and pressure ratings. Custom-made joints can also be designed and built to meet specific requirements.

Ease of Installation: The dismantling joint system allows for quick and straightforward installation and removal of pipeline components, reducing downtime and labor costs.

Versatility: GCF’s mechanical joints can be used with virtually any flange drilling or pressure rating, making them highly versatile and adaptable to different pipeline configurations.

Health and Safety Procedures

At GCF, the health and safety of our employees and customers are paramount. We adhere to stringent health and safety protocols during the manufacturing process of mechanical joints to ensure a safe working environment and high-quality products. Our procedures include regular safety training, the use of personal protective equipment (PPE), and strict adherence to safety standards and regulations. These measures help prevent accidents and injuries, ensuring the well-being of our workforce and the reliability of our products.

Quality Assurance at Greater Cairo Foundries

Quality assurance is a cornerstone of our manufacturing process. GCF follows rigorous quality control measures at every stage of production to ensure that our mechanical joints meet or exceed industry standards. Our quality assurance protocols include material testing, dimensional inspection, pressure testing, and final product evaluation. By maintaining strict quality standards, we ensure that our mechanical joints deliver optimal performance, durability, and safety in all applications.

Advantages of GCF’s Mechanical Joints

Customization: Tailored solutions to meet specific client requirements.

Flexibility: Ability to handle low to medium volume productions.

Precision: Ensures high-quality, accurately replicated castings.

Versatility: Capability to work with various materials and complex geometries.

Cost-effectiveness: Optimization of processes for competitive pricing.

Collaboration: Working closely with clients to understand and fulfill their needs.

Conclusion

Greater Cairo Foundries’ mechanical joints are designed to meet the diverse needs of modern pipeline systems. With a wide range of sizes, easy installation, and high-quality construction, our mechanical joints provide reliable and efficient solutions for various applications. By adhering to strict health and safety procedures and maintaining rigorous quality assurance protocols, GCF ensures that our products deliver exceptional performance and durability.

Health and Safety Procedures for Manufacturing Flanged Adaptors

At Greater Cairo Foundries, health and safety are integral to our manufacturing processes. We implement comprehensive health and safety procedures to protect our employees and ensure the production of high-quality flanged adaptors. These procedures include mandatory safety training programs, regular health and safety audits, and the provision of appropriate personal protective equipment (PPE). We also enforce strict adherence to safety standards and regulations, ensuring a safe working environment. Our commitment to health and safety helps prevent workplace accidents and injuries, fostering a culture of safety and responsibility.

Quality Assurance for Manufacturing Flanged Adaptors

Quality assurance is a fundamental aspect of Greater Cairo Foundries’ manufacturing process. We implement stringent quality control measures at every stage of production to ensure that our flanged adaptors meet the highest standards of excellence. Our quality assurance protocols include thorough material testing, precise dimensional inspections, and rigorous performance evaluations. By maintaining strict quality standards, we ensure that our flanged adaptors provide reliable, long-lasting performance in various applications. Our dedication to quality assurance underscores our commitment to delivering superior products that meet and exceed customer expectations.

Stay Updated! Follow Our Latest News and Insights on Facebook and LinkedIn

Pipe Couplers

Pipe Couplers of Greater Cairo Foundries”

Overview of Ductile Iron Pipe Couplers

Straight couplings are essential for joining ductile iron (DI) pipes or pipes of different materials but with the same external diameter. At Greater Cairo Foundries (GCF), our couplings are designed with a center sleeve located between two end rings. These couplings are equipped with wedge-shaped elastomeric gaskets that separate the sleeve and end rings. As the tie bars are tightened, the end rings are drawn together, compressing the gaskets between the end rings and the center sleeve onto the surface of the pipe, forming an effective, leak-proof seal. Our comprehensive range is available from DN80 to DN2600, making them suitable for use with ductile iron pipe spigots.

Applications of GCF Pipe Couplers

GCF pipe couplers are versatile and can be used in a variety of applications, including:

-

Pumping stations

-

Water treatment works

-

Sewage treatment works

These couplers ensure a secure and reliable connection, maintaining the integrity of the pipeline system.

Features and Benefits of GCF Pipe Couplers

GCF pipe couplers offer numerous benefits, such as:

-

Effective leak-proof seal

-

Compatibility with various pipe materials having the same external diameter

-

Wide range of sizes (DN80 to DN2600)

-

Easy installation and maintenance

The design and construction of our couplers ensure durability and long-term performance in various environments.

Health and Safety Procedures in Manufacturing Pipe Couplers

At Greater Cairo Foundries, we prioritize the health and safety of our workforce during the manufacturing process of pipe couplers. Our stringent safety protocols include regular training, the use of personal protective equipment (PPE), and adherence to safety guidelines. These measures ensure a safe working environment and the production of high-quality pipe couplers.

Quality Assurance in Manufacturing Pipe Couplers

Quality assurance is a critical aspect of our manufacturing process at GCF. Each pipe coupler undergoes rigorous testing to ensure it meets industry standards and customer specifications. Our commitment to quality ensures that our pipe couplers provide reliable and long-lasting performance.

Introduction

Greater Cairo Foundries (GCF) is renowned for its extensive range of ductile iron pipe couplers, designed to ensure leak-proof connections in various applications. These couplers are crucial for joining ductile iron (DI) pipes or pipes of different materials with the same external diameter. Our couplers are engineered to provide a secure and reliable seal, maintaining the integrity of the pipeline system.

Design and Construction

GCF pipe couplers consist of a center sleeve located between two end rings, separated by wedge-shaped elastomeric gaskets. When the tie bars are tightened, the end rings are drawn together, compressing the gaskets between the end rings and the center sleeve onto the surface of the pipe. This process forms an effective, leak-proof seal. The couplers are available in a comprehensive range from DN80 to DN2600, making them suitable for a wide variety of applications.

Applications

GCF pipe couplers are versatile and can be used in several critical applications, including:

- Pumping Stations: Ensuring secure connections in pumping systems, preventing leaks and maintaining efficient operation.

- Water Treatment Works: Providing reliable seals in water treatment processes, essential for maintaining water quality and system integrity.

- Sewage Treatment Works: Ensuring leak-proof connections in sewage treatment systems, crucial for environmental protection and system efficiency.

Features and Benefits

GCF pipe couplers offer numerous advantages:

- Leak-Proof Seal: The design ensures an effective seal, preventing leaks and maintaining system integrity.

- Compatibility: Suitable for joining pipes of various materials with the same external diameter.

- Wide Range of Sizes: Available in sizes from DN80 to DN2600, catering to diverse application requirements.

- Easy Installation and Maintenance: Designed for straightforward installation and ease of maintenance, reducing downtime and operational costs.

Health and Safety Procedures

At Greater Cairo Foundries, we prioritize health and safety during the manufacturing process. Our protocols include:

- Regular Training: Ensuring all employees are trained in the latest safety procedures.

- Personal Protective Equipment (PPE): Mandatory use of PPE to protect workers from potential hazards.

- Adherence to Safety Guidelines: Strict compliance with industry safety standards to maintain a safe working environment.

These measures not only protect our workforce but also contribute to the production of high-quality pipe couplers.

Quality Assurance

Quality is at the forefront of our manufacturing process. Each pipe coupler undergoes rigorous testing to ensure it meets industry standards and customer specifications. Our quality assurance procedures include:

- Material Testing: Ensuring the materials used in manufacturing meet the required standards.

- Dimensional Accuracy: Verifying that each coupler is produced to precise dimensions for a perfect fit.

- Performance Testing: Testing the couplers under various conditions to ensure they perform reliably in the field.

Our commitment to quality ensures that GCF pipe couplers provide long-lasting and dependable performance in all applications.

Conclusion

Greater Cairo Foundries’ ductile iron pipe couplers are designed to meet the highest standards of quality and performance. With a comprehensive range of sizes and applications, our couplers provide reliable and leak-proof connections in pumping stations, water treatment works, and sewage treatment works. Our dedication to health and safety, coupled with stringent quality assurance processes, ensures that GCF pipe couplers are a trusted choice for engineers and contractors worldwide.

Health and Safety Procedures at Greater Cairo Foundries

Health and safety are paramount at Greater Cairo Foundries. Our manufacturing process for pipe couplers includes regular training for all employees on the latest safety procedures. We enforce the use of personal protective equipment (PPE) and adhere strictly to industry safety guidelines. These measures ensure a safe working environment and protect our workforce from potential hazards, contributing to the production of high-quality pipe couplers.

Quality Assurance at Greater Cairo Foundries

Quality assurance is integral to our manufacturing process. Each pipe coupler at Greater Cairo Foundries undergoes rigorous testing to ensure it meets industry standards and customer specifications. Our procedures include material testing, dimensional accuracy verification, and performance testing under various conditions. This commitment to quality ensures that our pipe couplers deliver reliable, long-lasting performance in all applications.

Stay Updated! Follow Our Latest News and Insights on Facebook and LinkedIn